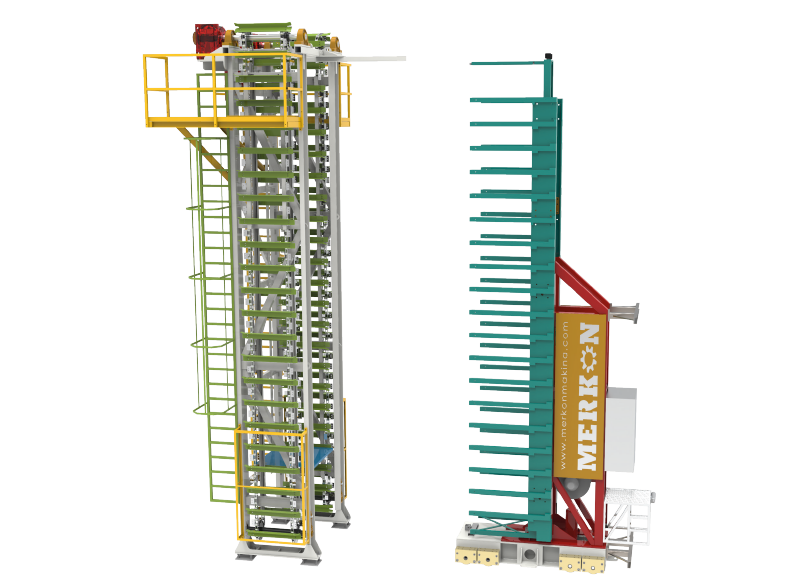

Finger car

elevator towers

Block Plant Completing

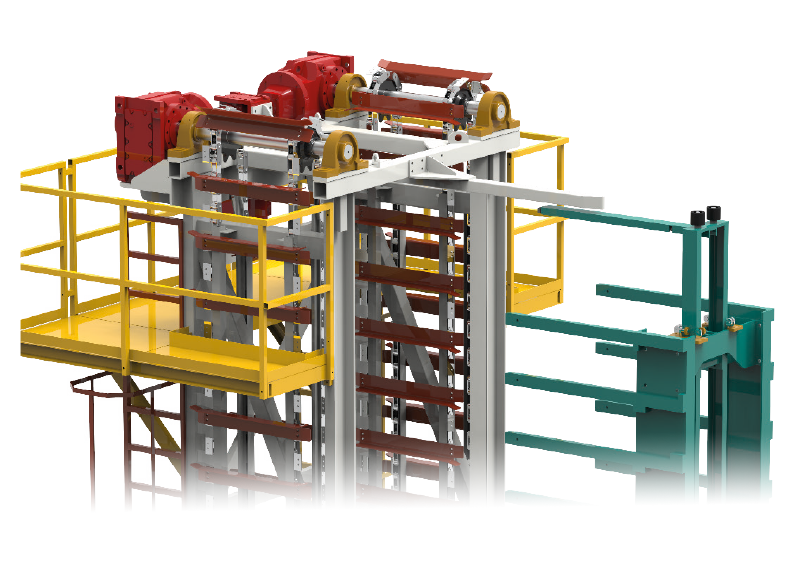

The high quality / top speed class machines can only achieve maximum efficiency when they are backed up with same class handling systems.

Among other handling solutions, a finger car type block plant is the one with the least hassle and maximum benefits by far.

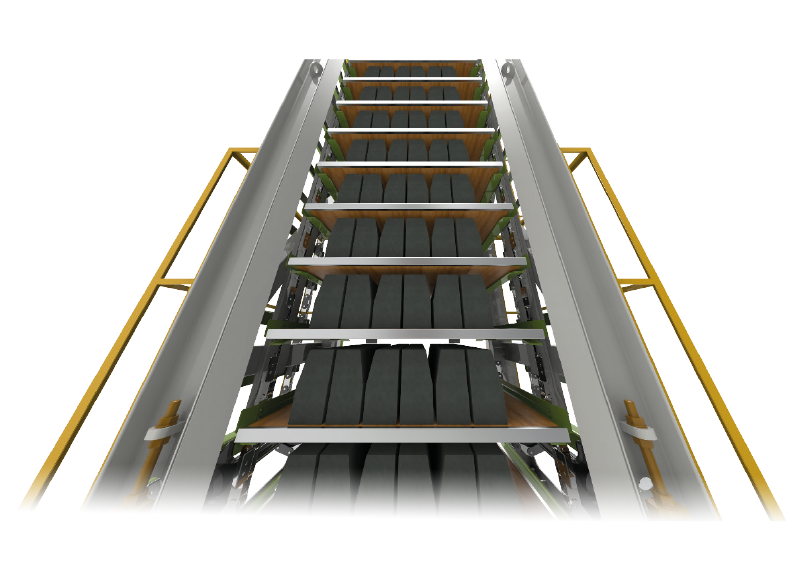

Having a smooth operation from pressing

to packing is the main thing that will automatically increase the profitability due to non occurring costs of losses.

Railed system will also benefit as forming a room for curing. This room can be closed separately, in a way to trap the heat inside to aid setting of the concrete.

The curing chambers shall be equipped with

ventilators, heat pumps, vapor generators

and A series of complementary systems like

measuring sensors and flow control devices.

Suitable to use with extra wide pallet alignment or excess height elements production. Custom programmable stacking ensures the handling to not be a limit of manufacturing all types of concrete products.

| Type | Pallet Capacity | Pallets at each floor | Minimum Ceiling | Min. Curing Area for 3000 Pallets |

| 20FC | 20 | Single | +10m | 2400M2 |

| 32SC | 32 | Double | +8m | 3000M2 |

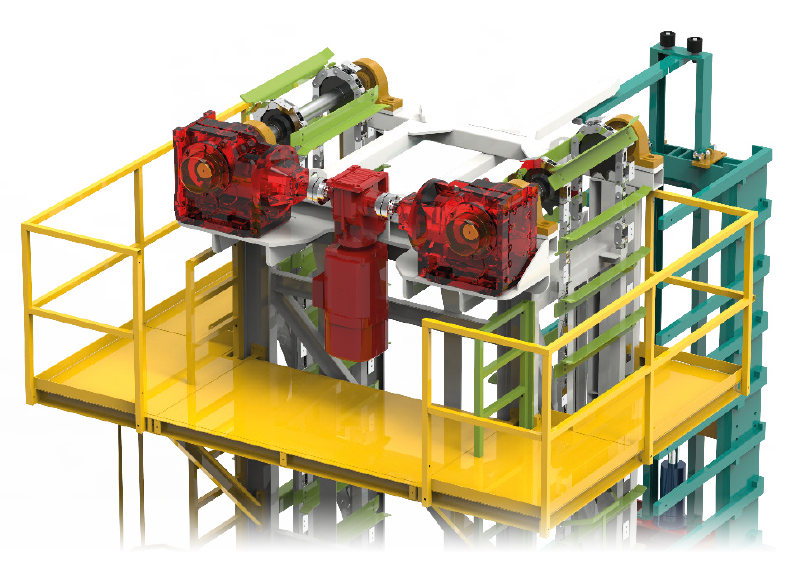

No matter how the shape or the weight of the product on the line, finger-tower alignment control minimizes the machine fatigue due to constant loads. Proper drive is also essential to keep the line out of down times occured in handling zone.

No matter how the shape or the weight of the product on the line, finger-tower alignment control minimizes the machine fatigue due to constant loads. Proper drive is also essential to keep the line out of down times occured in handling zone.

A niche collaboration with the World famous drive units producer SEW, three-way gear application successfully made on stacking towers. An absolute level is maintained with Double Shaft separetor design. Unlevel stacking would result as high losses in the production.