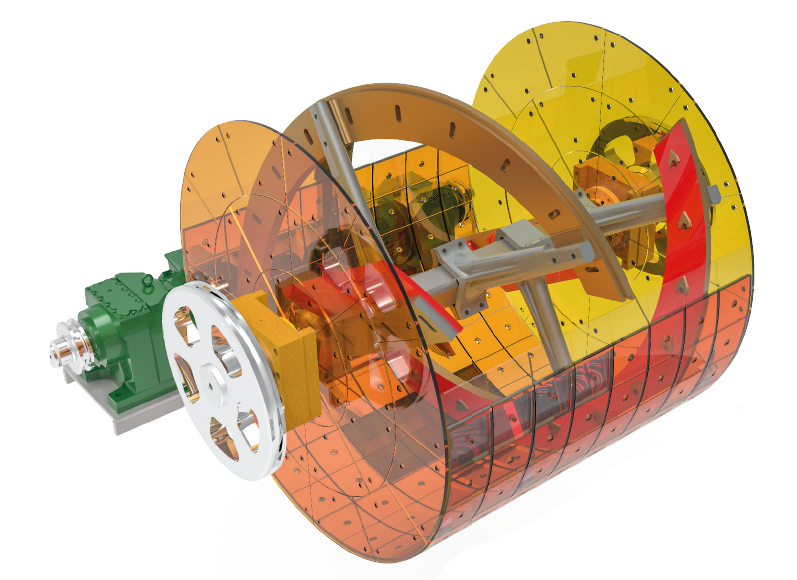

Ni-Hard 4 cast iron wearing plates that keeps the mixer functioning for a decade. Strong as requested to serve concrete business. Strong arms that are robust enough to ensure strength.

Single Shaft Mixer

Batching Systems

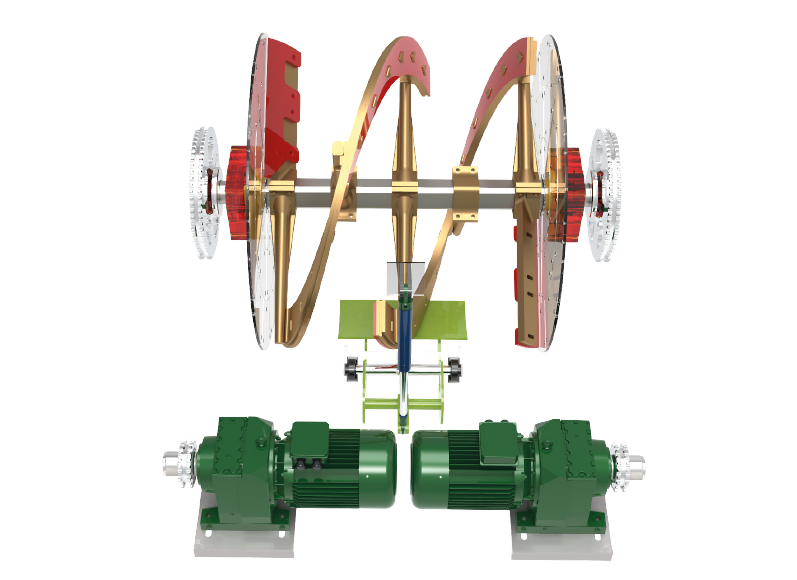

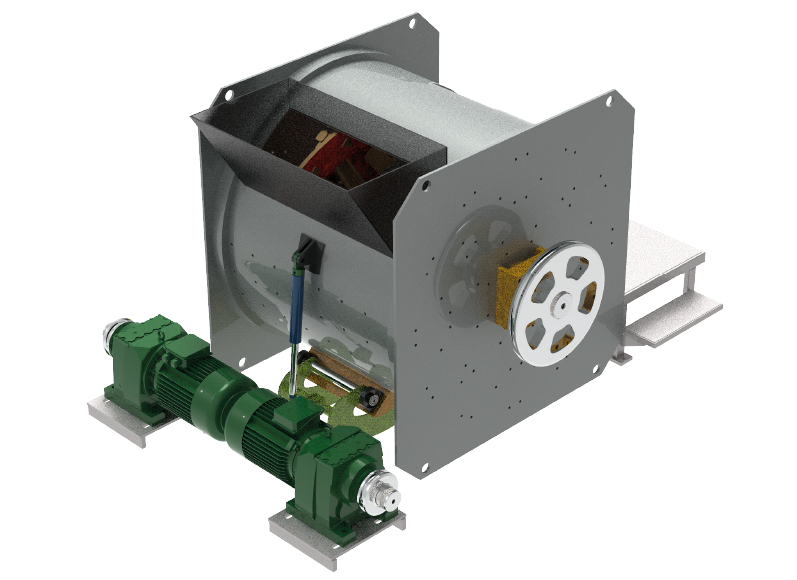

While water/cement ratio in a concrete batch determines the reaction time, slump does not only depend on water. Density of the batch should be the main value that has to be considered when it comes to picking the right mixer that a plant needing. Neglecting the geographical exclusions, mixture in a block plant gets pressed within 5 minutes after water meets with the cement. That means the system intolerant to any stoppage times including emergency ones that are out of possibility of prevention. The only solution is a double side motor driven single shaft mixer that can easily operate with 2.4 g/cc density, which corresponds to 2400kg/m3, even in an electricity cut getting back to mixing is never a trouble for Merkon SS series.

| Single Shaft Mixer | Motor Power | Max Mixing Weith | Ni-Hard 4 blades |

| 250SS | 30 | 750 | Optional |

| 500SS | 45 | 1500 | Optional |

| 1000SS | 45*2 | 2750 | Optional |

| 1500SS | 60*2 | 4000 | Optional |

Especially in high density dry mixes, the total weight of the mortar in the mixer gets real high as volumes increase. Even without cement settling it is a challenge. Merkon single shaft mixers with double motors, operate smoothly in extreme loads, even through an electricity cut in the middle of mixing.

The helical form of the blades constantly pushes the mortar towards the center, causing all of it to be swiped from the ou-t er walls to gather in the middle. This type of mixing does not lead to clumping of the bulky elements in the batch, maintains the homogeneity at all weather conditions and mixture recipes.